Industrial fans are designed to operate longer, supply greater airflow and pressure and meet more stringent environmental and ambient requirements compared to a general purpose or commercial HVAC fan. The heavy-duty materials and components used in an industrial fan may include thicker material gauges, larger shafts, bearings with increased bearing life, high-temperature features, and corrosion-resistant materials.

Unlike industrial fans, general purpose fans use less expensive materials and components and are designed for the residential or light-duty commercial markets. These fans are used in homes, appliances, and small ventilation systems. Cincinnati Fan does not manufacture any general purpose fans.

The characteristics of the two types are as follows.

| General Purpose Fans | Industrial Fans | |

|---|---|---|

| Material Gauges: | Light gauge sheet metal and plastic | 10-gauge plate material; cast aluminum and stainless steel construction available |

| Construction: | Tabs and lock seams | Continuous welds |

| Bearings: | Sleeve or strap type; short bearing life | Ball or roller bearings in cast iron bearing housings for longer life |

| Motors: | Light-duty, sleeve bearings, no service factor, minimum design features, Open Drip Proof enclosure | Continuous duty, ball bearings with service factors, special design features, generally TEFC or EXP enclosures |

| Safety Factors: | Slower wheel and shaft speeds | Much higher wheel and shaft speeds |

| Air Flow: | Generally limited to 2,000 CFM or less | From 200 to over 100,000 CFM |

| Pressures: | Generally .10″ to 4.0″ static pressures | From .50″ to over 100″ static pressures |

Centrifugal vs. Axial

Cincinnati Fan classifies our industrial air moving devices as either a fan or a blower. Additionally, depending on the way air is moved, it can be either centrifugal or axial.

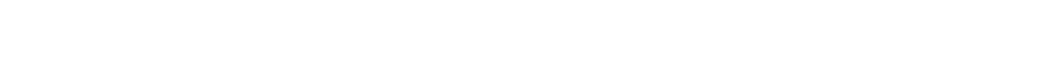

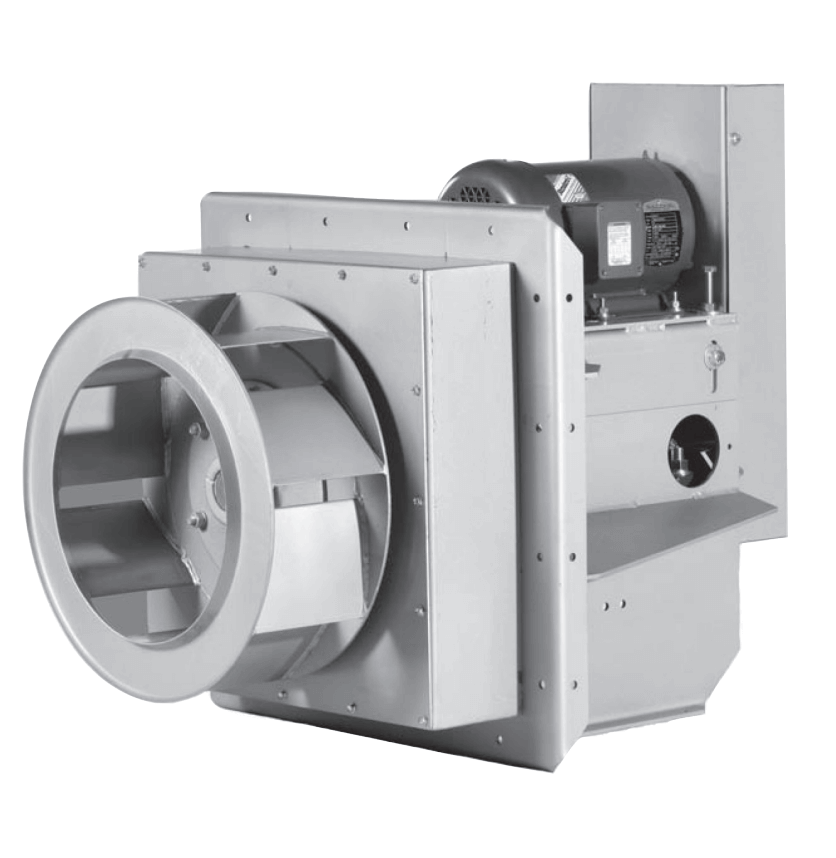

If the device uses a type of wheel to move the air, it is typically referred to as centrifugal and can be a fan or blower. The air enters the fan wheel through the housing inlet, turns 90 degrees, and is accelerated radially before exiting the fan housing.

If the device uses a type of propeller to move the air, it is typically referred to as axial and is a fan. The propeller draws the air into it and discharges it in the same axial direction.

Centrifugal Fans and Blowers

Centrifugal fans and blowers use a type of wheel to draw air into the inlet of the housing where it is then turned 90 degrees and accelerated radially before exiting the fan housing. Centrifugal blowers are designed to draw or push air at high pressures while centrifugal fans are designed to draw or push larger volumes of air at lower static pressures.

Common Applications of Centrifugal Fans and Blowers

- Conveying material in dust collector systems or loading to silos, trucks, and railroad cars.

- Combustion air for burners and industrial water heaters.

- Cooling electrical equipment or parts from heat curing ovens and kilns.

- Cooling power generators at electrical substations.

- Pressurizing cabinets, vaults, or rooms.

- Blow-off systems to remove moisture from parts prior to painting, coating or packing.

- General ventilation of rooms or factories.

- Providing suction or pressure for industrial process air flotation tables.

- Drying ink on cans and bottles, silkscreen and printing processes.

- Food processing.

- Circulating air in ovens and dryers.

- Forced ventilation of AC and DC motors and traction motors (motors used on large earth moving equipment, rapid transit systems, and overhead cranes).

Axial Fans

Axial fans use a type of propeller to draw the air into the fan and discharge it in the same axial direction. They are ideal for moving large volumes of air at low pressures. The most common types of industrial axial fans are tube fans (or duct fans), panel fans (or wall fans), personnel coolers, and air circulators.

Tube fans use a propeller, rotating in a round section of duct, which is mounted into ductwork of the same diameter to exhaust hot and/or contaminated air from a process or system. Tube fans can be direct drive with the propeller mounted directly on the motor shaft or belt drive with the propeller mounted on a separate fan shaft and driven by the motor through belts and sheaves. Other axial fans that incorporate the tube fan design are personnel coolers and air circulators. Panel fans use a propeller, rotating in a flat panel, which is mounted to a wall to exhaust air from a room or draw air into a room.

Common Applications of Axial Fans

- Exhausting contaminated, noxious fumes or hot air away from a process (i.e. paint spray booth, fume hood exhaust, welding booth)*.

- Process cooling and exhaust of machinery and/or systems.

- Spot cooling of heat generating equipment such as generators or transformers.

- General ventilation using supply air and/or make-up air in factories, warehouses, foundries, garages, laundries and transformers, engine, or equipment rooms.

- People cooling in hot work areas.

- Exhausting heat and cooling of kilns, forges, and in steel mills.

- Boosting airflow through long ductwork.

- Exhausting mist and vapor in paper mills or industrial parts washers prior to painting parts.

- Cooling large, diesel, engines and engine fluids that require a large volume of air blowing over the engine.

*Additional Information on Exhaust Ventilation

The term ventilation fan or exhaust fan is typically used to describe a fan that is used to exhaust contaminated, noxious or hot air away from workers and/or machinery. When the application doesn’t require long hose or duct runs, an axial fan is recommended, however, if the exhausted air needs to be moved a long distance through hose or duct work, a centrifugal blower is needed to supply the proper exhaust airflow at the higher static pressure required. The most common type of axial fan used for exhaust ventilation is a panel fan.

Maintaining a fresh air supply in work areas is essential for keeping workers healthy. If employees are exposed to amounts of contaminated air that exceed the levels permitted by US laws and regulations, their company is required to take immediate steps to remedy the matter. Just a few examples of work areas where contamination can be too high are spray painting areas or booths, abrasive blasting areas, grinding and polishing areas, welding areas, and dip tank areas.

The quantity of the supply air is determined by the physical size of the area to be ventilated. For a room, you would multiply the length times the width, times the height to determine the total cubic feet of the room. Divide the total cubic feet by a number of minutes per air change for the type of room you are ventilating. Your answer will be the CFM required to properly ventilate the room.

Volume of room (LxWxH)

———————————————— = CFM Required

No. of minutes per air change

A reference chart showing the average recommended air changes required for good ventilation, in different areas, can be found on page 8 of our Engineering Data catalog. However, this chart is a general guideline only. For specific requirements, contact an air quality engineer or agency trained in the requirements to avoid future problems. Two government agencies are NIOSH and OSHA.

Exhausting the air is only half the problem. When you exhaust the bad air, you must supply fresh replacement air. If you exhaust more air than you replace, you will cause the area to be under negative pressure, which is also unhealthy for workers over a prolonged period. Fresh air supply, or make-up air, is generally created with an air make-up system that includes a fan or blower, filters, shutters and dampers, heating or cooling coils, or both.

For information on how to select an industrial fan or blower, click here or download our Selecting a Fan or Blower manual.

FIND YOUR LOCAL SALES REP

Exceptional local support with over 170 experienced sales engineers in 56 offices strategically located across the U.S. and Canada to assist you.

START HERE